Core Business Areas

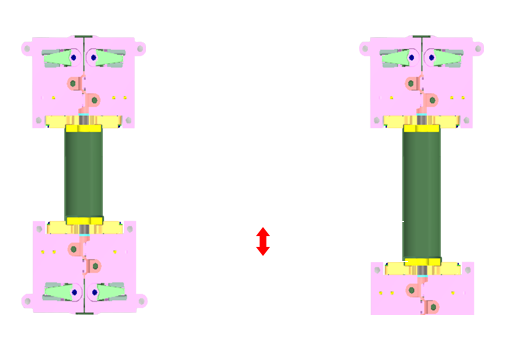

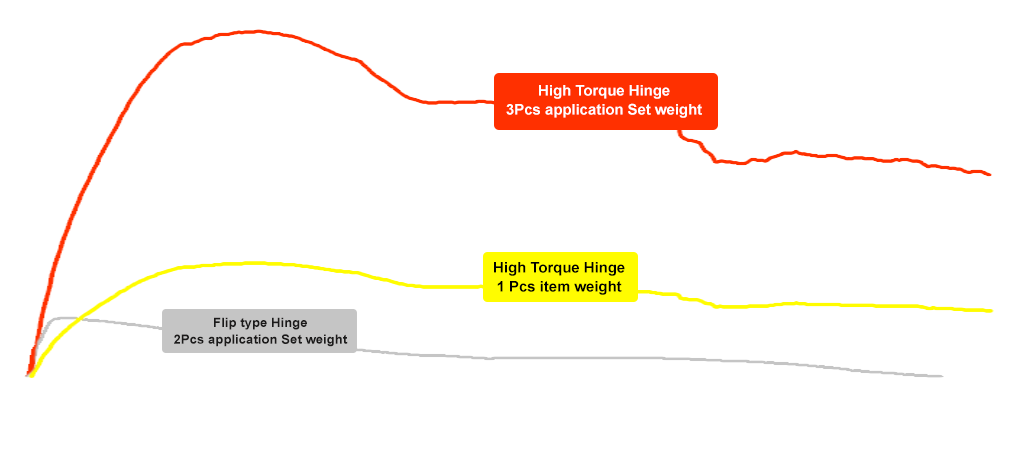

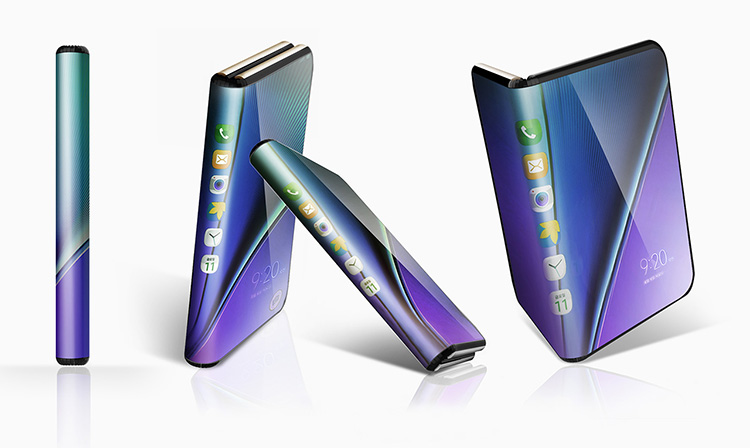

Foldable Hinge Mechanism

A key component that supports folding action through the device mechanism and minimizes the impact when panels come into contact

Slidable Mechanism

A multi-layer segmented structure plate applied to the underside of flexible panels for folding and sliding actions

Metal Injection Molding (MIM)

The technology that integrates plastic injection molding and powder metallurgy sintering techniques